This JLA-sponsored module explores the benefits of using ozone for decontamination, alongside the adverse health effects associated with the gas and considerations needed to mitigate them

Around 1.6 times heavier than air, ozone is a bluish gas whose molecules are made up of three oxygen atoms (O3). Its odour resembles newly mown hay and the odour threshold is approximately 0.01ppm. Ozone is always generated in situ, for immediate use, and it is extremely unlikely to be supplied as a commodity.

A powerful oxidising agent, ozone has a level of reactivity that means it rapidly decomposes to oxygen in both air and water. With an oxidation potential of 2.07V, the rate of decomposition is affected by temperature, humidity and air contaminants. This high oxidative power and rapid decomposition make it effective against a broad spectrum of microorganisms; hence its wide application for decontamination of indoor spaces, materials and surfaces, food and water.

Learning objectives

- Knowledge of the regulations surrounding ozone products

- Understanding the benefits of using ozone for decontamination

- Awareness of the adverse health effects associated with ozone and considerations that should be made before using an automated whole-room ozone disinfection unit

Ozone yields faster microbial inactivation kinetics compared with other oxidative agents used in chemical disinfectants and is effective on notably resistant microorganisms such as clostridium difficile. It can react up to 3,000 times faster with organic matter and is considered safer than chlorine, which produces harmful disinfection byproducts.

Beyond decontamination, ozone also possesses bleaching and deodorising properties, increasing its versatility in various industries. Nonetheless, the use of ozone for decontamination represents the most prevalent reason for its application.

Ozone generators produce a biocide insitu from ambient air or concentrated oxygen. This means there are no consumables required to achieve disinfection, resulting in a lesser impact on the environment. As ozone decomposes to oxygen, there are also no harmful chemical residues left after use.

Natural beginnings

Ozone is a naturally occurring gas generated in a high atmospheric layer by the action of ultraviolet (UV) light from the sun on oxygen. In the lower atmosphere, ozone is produced from the photochemical oxidation of atmospheric pollutants such as oxides of nitrogen and hydrocarbons in the presence of oxygen. It is also produced as an incidental byproduct of many industrial activities such as photocopying. Due to its reactivity, it is extremely difficult to store and transport.

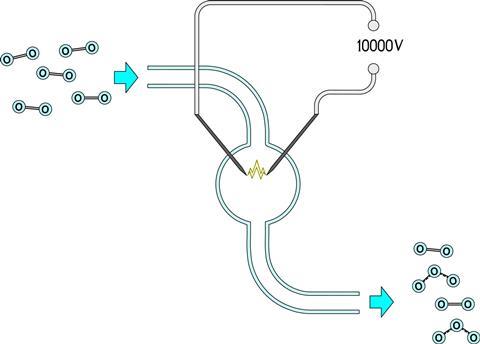

Ozone is produced industrially by bombarding oxygen with UV radiation or by passing air through a high-voltage electrical discharge. The efficiency of ozone generation (absorption of UV radiation by oxygen) depends on wavelength, with a maximum efficacy at approximately 160nm. The process also depends on the spectrum (and power) of the lamp, as well as moisture (humidity), oxygen concentration and temperature.

The most common method of producing ozone commercially is electrical discharge, or corona discharge. A corona discharge is a diffused spark through a dielectric (insulating material or a very poor conductor of electric current) to spread out the electrical discharge to a large area for maximum efficiency. Corona discharge generators are much more sophisticated than UV and can generate much higher levels of ozone.

Ozone is used for a wide variety of industrial purposes, including:

- To improve air quality in offices and as an odour suppressant in hotel rooms, commercial kitchens and cafeterias, food processing plants, chemical plants, sewage treatment works and cold stores

- As a disinfectant in the production of drinking water

- To overcome problems of taste, odour and peaty colour in drinking water

- As part of the water treatment process in the removal of pesticides

- As a disinfectant in swimming pools and hot and cold water systems

- For pre-treatment in coating applications – including inks, wood finishing, metal decorating and general industrial finishing

- For pre-treatment of plastic surfaces immediately before printing

- As a bleaching agent in the textile and foodstuff industries

- As a reaction initiator in the chemical industry.

Precautionary measures

Since ozone is a highly reactive substance, any adverse health effects will be found at the sites of initial contact: the respiratory tract (nose, throat and airways), the lungs and, at higher concentrations, the eyes. The principal health effects are produced by irritation of and damage to the small airways of the lung. However, people have considerable variation in sensitivity.

The current workplace exposure limit (WEL) for ozone is 0.2ppm in air averaged over a 15-minute reference period. When using ozone, adequate control should be achieved, as far as reasonably practicable, by the use of process or engineering controls. Where these measures are not adequate, you should consider further controls, such as improved systems of work and the use of respiratory protective equipment.

If someone is overcome by ozone, the following first aid precautions should be adopted (as set out in the Health and Safety Executive publication Ozone: Health Hazards and Precautionary Measures):

- Remove the person to a warm uncontaminated atmosphere and loosen tight clothing at the neck and waist

- Keep the person at rest

- If the person has difficulty breathing, oxygen can be administered by a competent individual using the appropriate equipment. A competent individual is an occupational health professional or workplace first-aider who has received training in oxygen administration and whose competency is assessed regularly

- If the person is not breathing normally then start cardiopulmonary resuscitation – individuals undertaking this action should be either first-aiders who hold a current qualification in workplace first aid or are occupational health professionals considered competent in accordance with the current basic or advanced resuscitation protocols of the UK Resuscitation Council

- Seek medical help.

Technical standards and regulations

When considering ozone as a means of disinfecting your rooms and surfaces, it is important to know that Biocidal Products Regulation (BPR) (EU) 528/2012 dictates that anyone marketing an ozone generator for a biocidal application within the EU must have their product authorised in line with this regulation.

All disinfectant products are subject to European regulations. The BPR covers both off-the-shelf disinfectants as well as those that generate chemicals in situ. The regulation ensures that a product’s performance meets recognised standards and that no adverse effect on the environment, human or animal health exists as a result of its use.

The BPR process runs over two stages. Initially the active substance (AS) – in this case, ozone – is put forward for validation. The deadline for submission of the AS dossier was September 2016, and ozone was successfully approved as a biocide in July 2023. The second stage is to gain approval for specific products.

In order to claim a gaseous ozone unit can be used for the disinfection of surfaces, it must be tested against EN 17272:2020 Chemical disinfectants and antiseptics – Methods of airborne room disinfection by automated process – Determination of bactericidal, mycobactericidal, sporicidal, fungicidal, yeasticidal, virucidal and phagocidal activities. There is currently no EN standard to test against in order to claim disinfection of air.

The process of validating ozone products for the BPR is both time-consuming and expensive, with potential costs in excess of £100,000 per product. Such a large financial commitment deters many businesses from achieving the necessary standards for legally marketing and supplying ozone products.

When in use

When using an ozone generator for whole-room disinfection, a typical unit tends to be handheld or wheel-based, the latter tending to be larger and with a higher ozone output. All units will differ in how they are built but will have similarities such as an in-built ozone generator (be that UV or corona) and an in-built fan, to distribute the ozone into the room.

Some units will have an in-built safety feature often referred to as a “destruct” this would typically be an automatic phase of the cycle which draws the ozonated air from the room through filters containing elements such as carbon which aid the rapid decomposition of ozone back to oxygen. This should kick in post ozone generation to reduce the levels in the room to a safe level (below the WEL) for when the cycle finishes. This is an essential part of a generation cycle to ensure rooms are safe to reoccupy after treatment.

Another example of a safety feature that should be considered when using an ozone unit is an external monitor and indicator that can be seen by the operator to alert them to when it is or is not safe to enter the room.

Using an ozone disinfection unit should never replace manual cleaning; it should be used as an additional, top-up disinfection procedure. If the unit is effective at distributing the ozone, it will be able to reach areas of the room that manual cleaning cannot.

Certain considerations should be made before using an automated whole-room ozone disinfection unit. When using such a unit:

- Treatment areas must be unoccupied by humans

- All plants and animals should also be removed

- Ozone is incompatible with items made of natural rubber and exposure can cause weathering, so where possible, such items should be removed

- Ensure that the room or area to be treated is completely sealed to avoid ozone seeping into occupied areas

- In situations where there is a risk of people re-entering the rooms, lock or seal doors by an agreed method and inform everyone likely to enter the room that it will be out of use for the length of the sanitising process

- Ensure safety notices and warning signs are placed at all entrances to the room to be treated

- Do not place the sanitiser directly below a smoke alarm as there is a risk of activation of the sensor in this situation. If it is safe to do so, it is recommended to deactivate the zone at the fire panel or cover the sensor head

- Where the system is equipped with a ventilation inlet and outlet, neither should be obstructed by foreign objects that could block or restrict the airflow

- When available, an external “safe to enter” monitor and indicator should be placed in a position where it can be visually seen from outside the room

- The unit should be operated only by trained professionals.

Maintenance

Maintenance procedures and schedules will be machine dependent but are likely to be relatively similar, depending on the method of ozone generation. The type and frequency of the maintenance tasks fundamentally depend on the operating environment as well as on the duration and type of use.

In the course of using an ozone generator, dust and moisture can accumulate in or on the components, which might compromise functionality and efficiency. In rooms with a high volume of dust and dirt or high moisture levels, maintenance may need to be more frequent. In dry surroundings, frequency of servicing can be reduced.

Operators should never access and interfere with internal components; these should be maintained strictly by trained engineers only. When the method of generation is using UV-C, the engineer must ensure they are using the correct PPE. UV-C can be extremely dangerous to the human eye when proper protection is not worn, so no untrained or unprotected individuals should be in the vicinity of the unit during UV lamp maintenance.

The lamps require cleaning to remove dust, which should be done using a specialised solution. Any oil and grease residue on the lamps from incorrect cleaning fluid or touching the lamps with bare hands will attract heat and produce hot spots on the lamps, resulting in a reduced lifespan.

The electrical discharge generation method may use glass electrodes in the ozone cell; these are much simpler to clean but still should not be touched with bare hands. They will require cleaning with a cloth to remove any dust and dirt.

Any damage to internal features such as the fan, filters or electrical components should be assessed and fixed if necessary; fans and filters may also require cleaning. Maintenance by the operator must be carried out only on the exterior of the unit. Before doing so, the operator must ensure the unit is disconnected from the mains supply, and the cable should be visually inspected for damage. The external cabinet of the unit should be regularly wiped down, and any filters or fans visible to the operator should be cleaned of dust as necessary.

Awaab’s Law

The Social Housing (Regulation) Act 2023 lays foundations for changes to how social housing is managed. It includes increased regulation of social landlords and new rules for protecting tenants from serious hazards in their homes. Many of the provisions in this legislation are in response to the tragedies of the 2017 Grenfell Tower fire and the death of two-year-old Awaab Ishak, who died in 2020 from exposure to serious mould.

The intent of Awaab’s Law is to prevent another such tragedy and for social landlords to understand exactly what they need to do, and by when, if one of their residents reports a hazard in their property.

Awaab’s Law effectively inserts (or, in legal terms, “implies”) into social housing tenancy agreements a term that requires landlords to comply with new requirements, which are to be set out in regulations. This means all registered providers will have to meet these requirements, and if they do not then residents will be able to hold their landlords to account by taking legal action through the courts for a breach of contract.

Legal proceedings should not get in the way of landlords taking action on repairs. Residents and landlords can and should continue to engage on repair works even if legal proceedings are under way or if a complaint is with the Housing Ombudsman.

Using an ozone generator that has been approved for biocidal use will enhance manual deep cleaning processes already in place to reduce mould on surfaces and in the air. Ozone effectively breaks down the outer membrane of fungus cells, causing them to die. This will not address the cause of the mould and, if appropriate remediation work is not carried out, it can return. However, it is an effective method of reducing mould to a safer, more manageable level, thereby supporting landlords to meet the time-limit requirements for responding to repairs.

Please fill out the form below to complete the module and receive your certificate:

No comments yet